About us

Founded in 2003,we can provide you with complete energy plant solutions.Zhengzhou Dingli has four series of products with high scientific and technological content, such as Drying series, Dehydration series, Heat source series and Crushing series.

We not only possess an independent technology R&D team who have obtained a number of utility model patents and invention patents, but also have the professional manufacturing team and after-sales team to guarantee you the product quality and user experience.

Now, our products have sold well in more than 60 countries and regions around the world, winning great praise and trust of our customers all over the world! View More

-

Project description

Provide detailed project description and equipment configuration scheme.

-

Installation

Provide installation, commissioning and training service, has a professional team for after-sale service.

-

Warranty

All the products from DINGLI company has 12 months warranty since clients sign the act of acceptance.

-

Technical Support

Life time technical support, provide installation and debugging video and related materials.

-

On-line Service

24 hours on-line service.

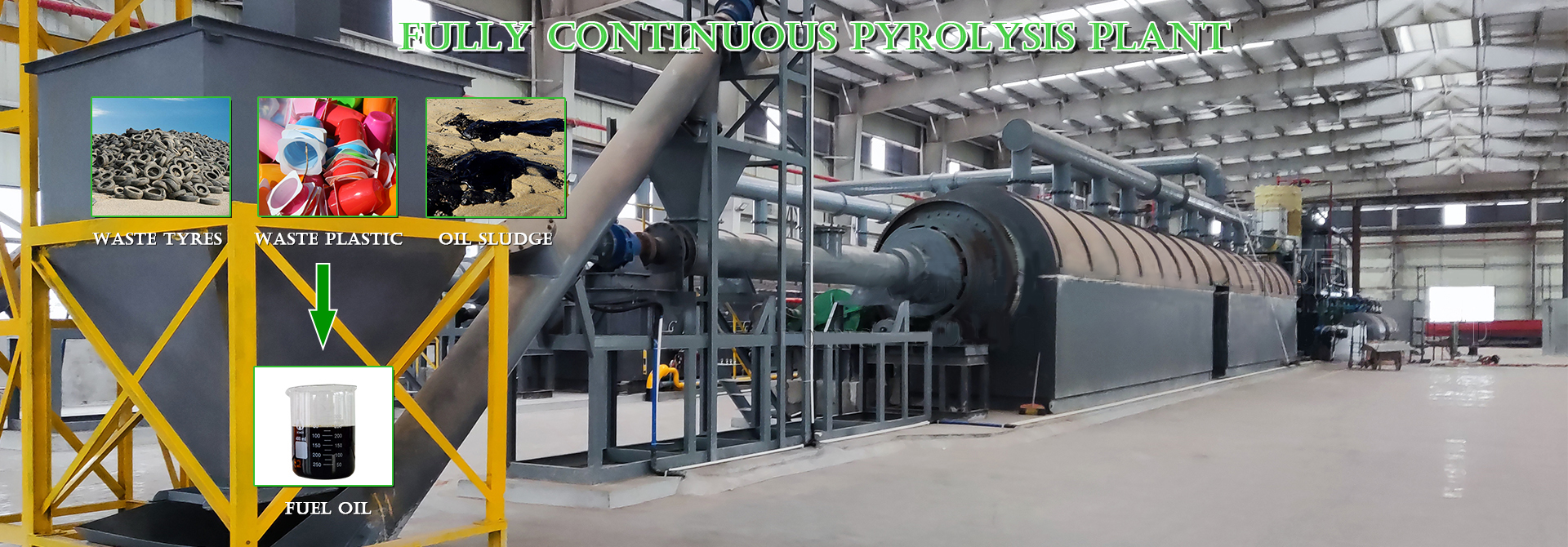

Waste tire to diesel recycling plant was put into operation in South Africa

- Raw Material: waste tires, waste plastics, oil sludge, coal tar

- Model: DY-C-20 DY-C-30 DY-C-50

- Operation System: Fully automatic PLC control system

Top Picks

View More >Dingli News

-

01-06

2026

What are the uses of the products from sludge pyrolysis?

Sludge pyrolysis is typically carried out in a dedicated pyrolysis reactor maintained at atmospheric or high pressure, with controlled temperature and anoxic co

-

12-25

2025

Sludge pyrolysis refers to a treatment method that decomposes sludge under an inert atmosphere and at a certain temperature. Because the pyrolysis process isola

-

12-19

2025

Can waste tires be pyrolyzed for oil?

Can waste tires be pyrolyzed for oil? Yes, waste tires can be pyrolyzed using a technology called pyrolysis, which breaks down rubber into oil, gas, and solid c

-

12-12

2025

Can all plastics be pyrolyzed?

Plastic pyrolysis is a popular method among plastic recyclers for converting waste plastics into useful resources such as fuel oil, gas, and carbon black. Howev

-

12-03

2025

How to Treat Waste Gas After Tire Pyrolysis?

Given the characteristics of tire pyrolysis waste gas, the treatment process typically includes the following steps:1. Waste Gas Collection: Waste gas from the

-

11-27

2025

Does sludge need dewatering before pyrolysis?

Sludge dewatering is a crucial step in sludge pyrolysis. Its core objective is to remove as much water as possible from the sludge, thereby significantly reduci

Industry News

-

01-06

2026

What are the uses of the products from sludge pyrolysis?

Sludge pyrolysis is typically carried out in a dedicated pyrolysis reactor maintained at atmospheric or high pressure, with controlled temperature and anoxic co

-

12-25

2025

Sludge pyrolysis refers to a treatment method that decomposes sludge under an inert atmosphere and at a certain temperature. Because the pyrolysis process isola

-

12-19

2025

Can waste tires be pyrolyzed for oil?

Can waste tires be pyrolyzed for oil? Yes, waste tires can be pyrolyzed using a technology called pyrolysis, which breaks down rubber into oil, gas, and solid c

-

12-12

2025

Can all plastics be pyrolyzed?

Plastic pyrolysis is a popular method among plastic recyclers for converting waste plastics into useful resources such as fuel oil, gas, and carbon black. Howev

-

12-03

2025

How to Treat Waste Gas After Tire Pyrolysis?

Given the characteristics of tire pyrolysis waste gas, the treatment process typically includes the following steps:1. Waste Gas Collection: Waste gas from the

-

11-27

2025

Does sludge need dewatering before pyrolysis?

Sludge dewatering is a crucial step in sludge pyrolysis. Its core objective is to remove as much water as possible from the sludge, thereby significantly reduci

What can be used in pyrolysis plant to heat the pyrolysis reactor?

Raw materials such as waste tires, waste plastics, and waste oil sludge can produce valuable products such as pyrolysis oil, carbon black, combustible gas, etc....

What’s the waste tire recycling machine price?

At present, there are various waste tire recycling machines on the market, including waste tire to fuel oil pyrolysis plant, waste tire packing&unpacking machin...

What machines are included in the fully continuous waste tire pyrolysis line?

A complete fully continuous waste tire pyrolysis line includes pretreatment system, feeding system, pyrolysis system, cooling system, odor disposal system and s...

How to purify waste engine oil to diesel?

How to make diesel fuel from old engine oil?

What to do with old motor oil?

How to converting waste lubricant oil to diesel fuel ?

Is it necessary to buy a tire shredder for fully automatic continuous pyrolysis plant?

How much does a tire shredding machine cost?

What is the function of Steel Bundle Machine?

What is the flow of Carbon black pellet Production Line?

MAIN ADVANTAGES OF CONTINUOUS PYROLYSIS PLANT

Fully Pyrolysis High Oil Output

Accurate calculated pyrolysis system, ensure fully pyrolysis to get high oil output.

Unique sealing design

Unique sealing design of both feeding and slagging system for safety guarantee and environment protection.

Save Time and Energy

Continuous feeding, continuous slagging, save time and energy.

Fully Automatic With Low Labour Cost

Fully automatic with PLC control system, save manpower, reduce labour cost.

Unique slaggig system

Unique slaggig system for direct and convenient carbon black and steel wire separation.

Big Capacity

Single unit, small land occupy size, but with large capacity.

contact us

CONTACT US-

Phone:

+86 157-3716-4169 -

WhatsApp:

+86 157-3716-4169 -

E-mail:

dingli@dlbio-dryer.com -

Wechat: